Tinkers Projects

Imagine | Develop | Create

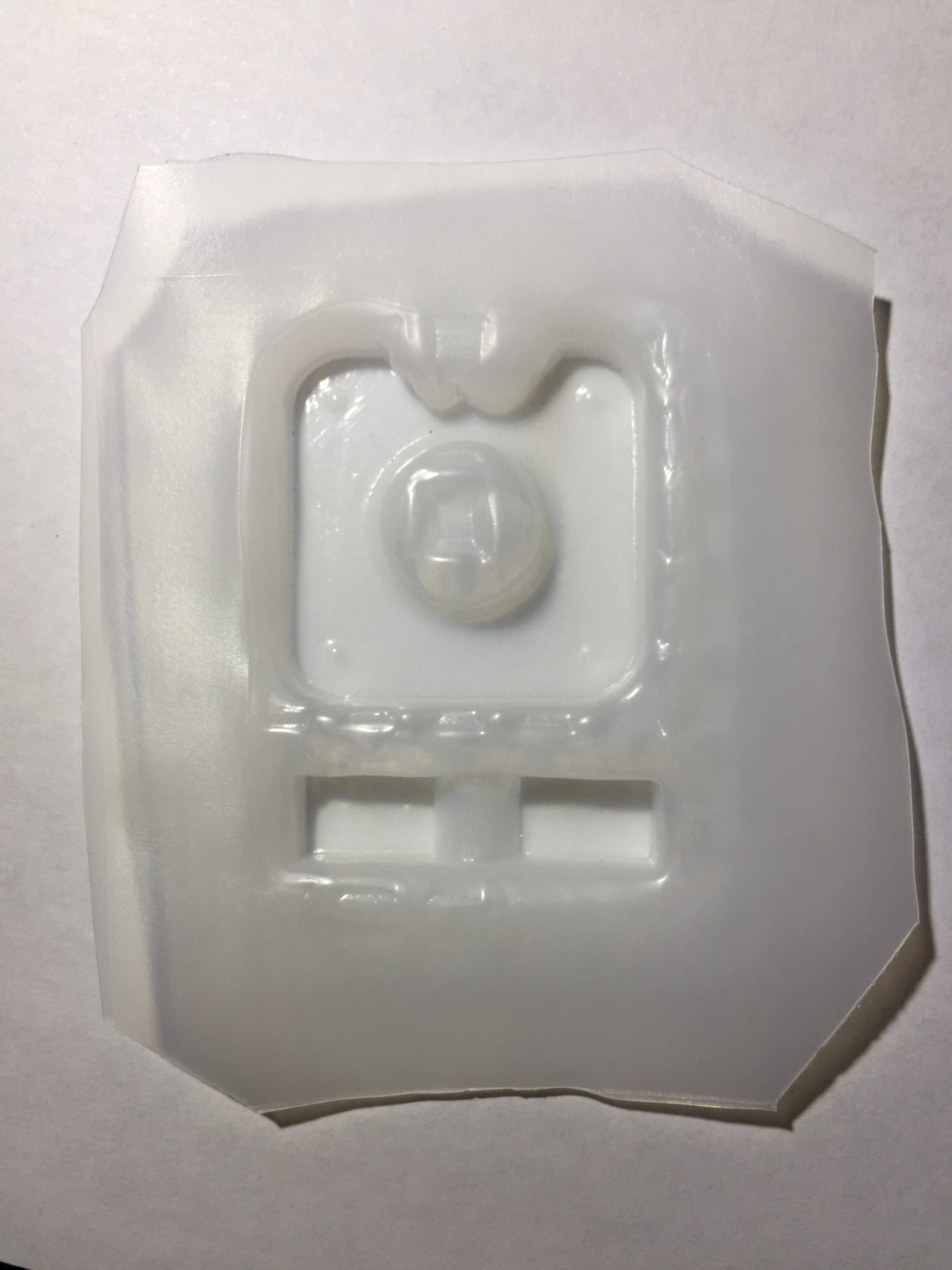

I wanted to see how easy it would be to vacuum form PE plastic from milk bottles and turns out you can. The Temperature and timing need to be adjusted but the first test worked out better than expected. After more experimentation, the vacuum forming process could make great forms. The Tool is made from PLYwood milled from a CNC machine and a 3D printed vacuum cleaner nozzle. The main PLYwood and 3D printed parts are glued together and the plastic holder is screw together with a PE sheet pushed between them. The PE sheet is cut from the side of milk bottles, the larger and flatter the better. The plastic holder is put into an oven to soften the PE plastic and the nozzle is attached to a vacuum cleaner. A buck or pattern is placed in the centre of the vacuum bed. Once the plastic is softened and is bow downwards, it is ready to form over the buck. Remove from the oven and place it quickly and carefully over the buck/bed. Once in place turn on the vacuum to seal the plastic over the buck and form it. Once cool and solid the plastic sheet can be removed and cut to make the formed part. https://www.youtube.com/watch?v=4WnLDfev1n8

I wanted to see how easy it would be to vacuum form PE plastic from milk bottles and turns out you can. The Temperature and timing need to be adjusted but the first test worked out better than expected. After more experimentation, the vacuum forming process could make great forms. The Tool is made from PLYwood milled from a CNC machine and a 3D printed vacuum cleaner nozzle. The main PLYwood and 3D printed parts are glued together and the plastic holder is screw together with a PE sheet pushed between them. The PE sheet is cut from the side of milk bottles, the larger and flatter the better. The plastic holder is put into an oven to soften the PE plastic and the nozzle is attached to a vacuum cleaner. A buck or pattern is placed in the centre of the vacuum bed. Once the plastic is softened and is bow downwards, it is ready to form over the buck. Remove from the oven and place it quickly and carefully over the buck/bed. Once in place turn on the vacuum to seal the plastic over the buck and form it. Once cool and solid the plastic sheet can be removed and cut to make the formed part. https://www.youtube.com/watch?v=4WnLDfev1n8