Dipping Machine Research Thesis Project

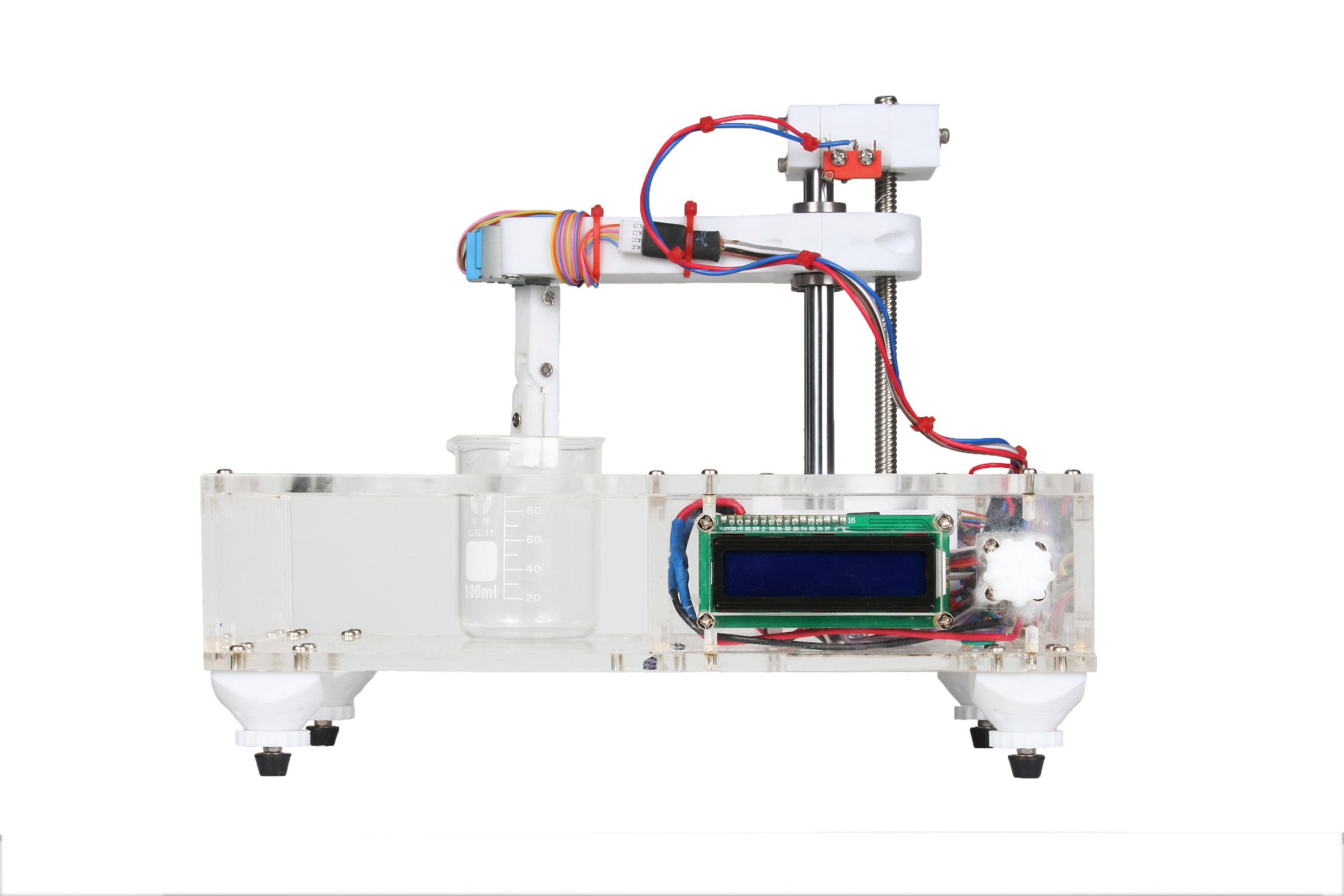

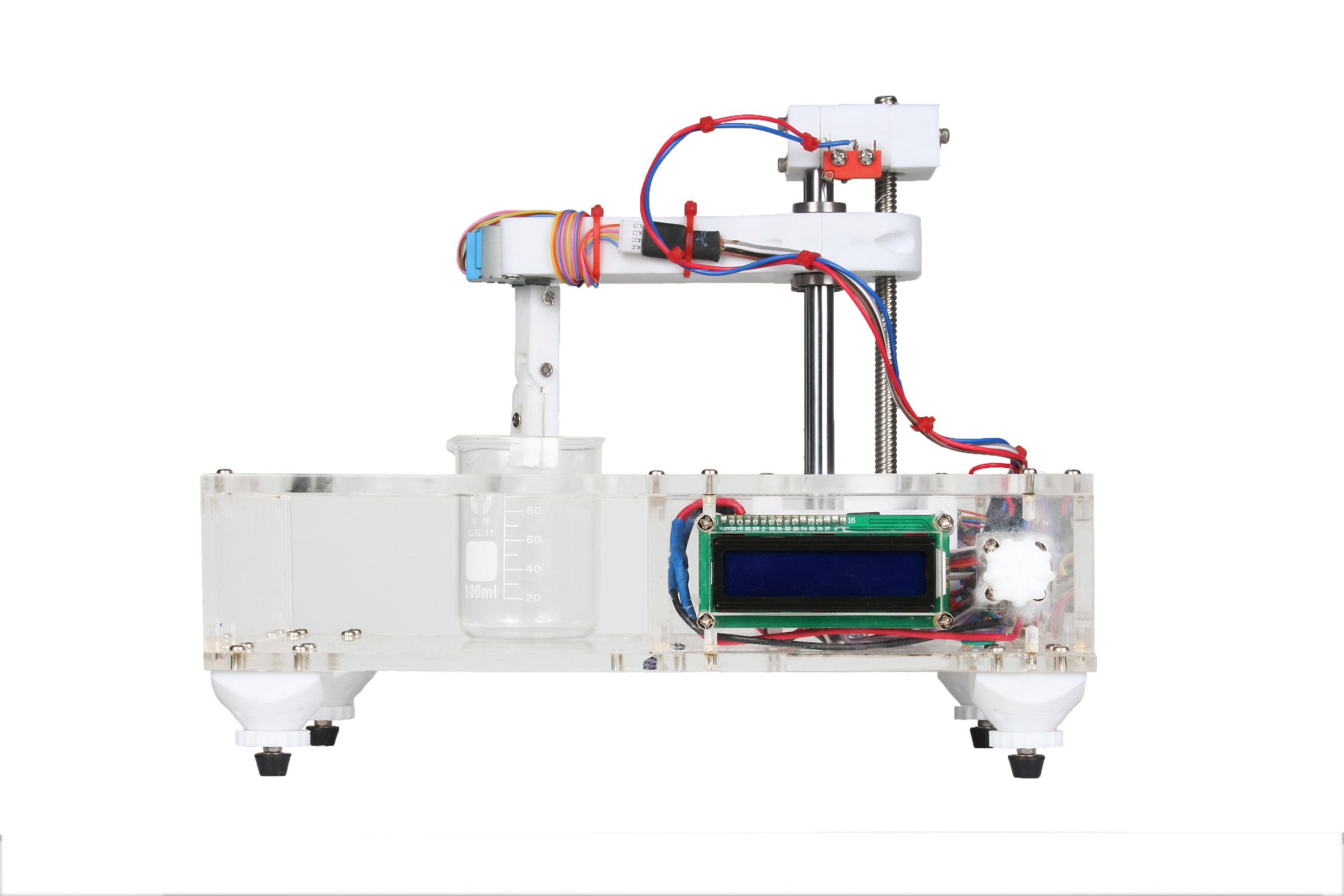

The base

The base design is done and is working well as the base. It will need to be changed a little for different functions, functions like dipping in multiple different solutions. The design allows this to be changed to preform different experiments in the future. The anti-spill has not been 100% tested but can see it having problems if spilt, leaking into the machine where the electronics is. This will need to be addressed in the future. The vibrations from the motors, vibrate the solutions, this may be fixed with an anti-vibration mount for the beaker. The dipping arm The construction of the arm took a while to start due to organising the part and them travelling to get here. The arm is constructed from 3D printed parts and works well as a prototype. The machine uses linear bearing to slide the overhanging up and down into the beaker which holds the liquid. On the arm where is another stepper motor to allow the sample to rotate around. A screw thread is used to pull and push the arm up and down allowing the arm to preform different functions. This dipping arm will not be able to perform as many different functions as the robotic arm but enough to find if there is a different in coats surface.Electronics

The same with the arms, the constructions of the electronics were delayed by the late shipping of the parts. The PCBs were provided for this project to try. The PLEX board provide greater flexibility than other Arduino development boards. The board has a LCD, SD and up to 32 inputs and outputs that will be required for this project. PLEX uses a ATMEGA328 which is the same as the Arduino UNO uses. Stepper motors move the joints in the Arm require drivers to control them. The drivers selected were HR4988 which require 2 control pins to make the stepper step in either clockwise (forwards) or anti-clockwise (backwards) direction. One pin is the directional and the other is the step, a pulse to the step pin will make the motor step in a direction dependent on the directional pin. If the directional pin is HIGH, the motor will spin one direction and if the directional pin is LOW then the motor will spin the other direction.The program

Everything function that the machine can do is programmed in. There are 2 main control functions, auto and manual. The auto function is to make using the machine easier, after entering all the settings that are required and selecting run, the machine will run using those settings. The auto function will dip down to a specified height then return to the starting point. The machine will restart itself every time to a limit switch. The manual function allows more control over the height because it does not get set. Selecting up or down allows the machine to move in that direction and does not need to be set back to a set point every time.